Introduction

With increasing demands on the efficiency in agriculture, precision farming is becoming more and more important. Precision farming indicates for the targeted management of utilized agricultural land, e.g. the individual application of fertilizers and plant protection products depending on the position of the utilized land.

To ensure the necessary communication between tractor, equipment and agricultural management software, the non-proprietary ISOBUS is used. ISOBUS is specified in standard ISO 11783-2 and describes the BUS including the connectors used with it.

To extend the CONEC product range in the field of connection solutions for agricultural and construction machinery, the connectors for ISOBUS are included in the ready-made and overmoulded design.

Currently, the contact carrier and the contacts of series HDP of the company Deutsch (TE) are finished and overmoulded at CONEC. This ensures that our customers are provided with 100 % controlled assemblies. Overmoulding offers optimum protection in harsh environments, as in agriculture, but also in the construction and mining industries.

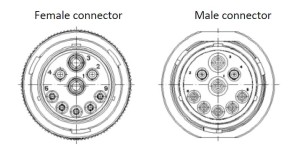

The contact carrier has the 9-pin contact layout specified by the standard.

Contact connection areas:

Contact 1 ground / 3 power: 2 x 5-10 mm²

Contact 2 ECU ground / 4 ECU power: 2 x 2-3 mm²

Contact 6-9 TBC and CAN bus: 5 x 0.5-1 mm²

Contact position 4 and 5 in the female connector

are internally bridged.

In the male connector, position 5 is not wired and not equipped.

Connection/locking of the two connectors is done via bayonet locking.

Currently, two different cable variants are available which are specifically designed for agricultural applications. The cable variants differ in the cross-section of the stranded wires for ground and power with 6 mm² and 10 mm².

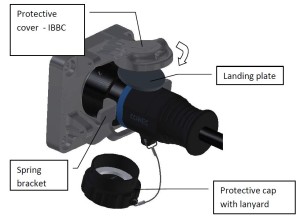

The CONEC ISOBUS connector assembly is plugged in on the tractor in the so-called IBBC [ISOBUS Breakaway Connector]. In the IBBC, the bayonet coupling is overridden and the connector is locked in place with a spring bracket.

In unmated condition, the IBBC is protected against moisture and dirt by a protective cap with integrated seal. To protect the seal of the protective cap in mated condition, the ISOBUS connector is equipped with a landing plate. The standard version is round, optionally there is also a landing plate with flattened outer surface. Upon request, the connectors can be supplied completely without landing plate.

In the following images, the colour of the landing plate was changed for better visibility (default colour “black”).

The landing plate is not provided for the male connector, but it is available upon request.

At the connection side, the female connector comes with a quick release bayonet locking. CONEC has developed a dust protection cap for the female version and uses it to protect the contact area against dirt and moisture. By default, the dust protection cap is connected to the connector by means of a captive stainless steel lanyard.

The contact carriers are overmoulded with durable TPU. TPU UL94 is approved and has fire protection class V-0.

The ISOBUS connector series is designed both as open end cable and as connecting cable.

CONEC provides a version with corrugated tube for better protection of the hybrid cable. In this version, the hybrid cable is protected by a corrugated tube which is integrated in the overmould geometry. The corrugated tube is made of durable plastic PA6. The material used is approved according to UL 94.

Items and designs

The overmoulded ISOBUS connector comes with a specially designed PUR hybrid cable with a stranded wire cross sections of 2 x 6 mm² + 2 x 2.5 mm² + 4 x 0.5 mm².

Alternatively, a hybrid cable with a stranded wire cross section of 2 x 10 mm² + 2 x 2.5 mm² + 4 x 0.5 mm² can be selected.

By default, the open end cables are offered in cable lengths of 2, 5, and 10 m. Connecting cables are available in cable lengths of 6, 9 and 12 m. Other lengths are available upon request.

Images of open end cables:

Images of connecting cables:

The corrugated tube can be used for both types of cables of the ISOBUS plug connector. Due to the integration into the overmould, continuous protection of the housing up to the cable is ensured. By default, a corrugated tube size NW 19 is used.

Benefits

• Robust and ergonomic design

• Version with or without landing plate

• Two cable types

• Version with additional corrugated tube

• Standard with captive dust cap (female connector)

• Due to the overmould, continuous IP67 protection of the housing up to the hybrid cable is ensured

• Use in harsh environments